Let’s review some tips for better DIY brake jobs. Despite aiming these tips at people that prefer to work on their own automobiles, retail auto service customers will also benefit from this information. Sometimes car repair shops and professional mechanics are forced into a situation where they cut corners.

These auto repair centers need to remain competitive and therefore operate on thin profit margins for standard brake job services. Unfortunately, many technicians today still get paid on the archaic flat rate pay scale. This means they’re not compensated all that much for brake services on your automobile. The necessity to put food on the table can push them to rush the job. Rushing the job on an automotive safety system seems counterproductive. However, in the real world it happens.

Knowing how to do DIY brake jobs correctly helps those retail customers ask important questions about how their brake service was performed. In this article we’ll focus on items that driveway mechanics can employ to achieve better results. Drivers having the service performed for them, can ask the mechanic if they employed the same tactics. One thing is for sure, the more time you spend on the little details the better these DIY brake jobs turn out. In fact, sweating the details can help the new friction pads last longer and reduce brake noise.

Brake Caliper Slide Issue

The brake caliper on all automobiles is a free-floating component. The caliper physically moves when you apply the brakes and then returns when you release them. Manufacturers implement the use of caliper slides differently. In fact, on some old Mercedes-Benz cars the caliper is actually fixed and the pads slide inside the caliper.

Despite the design, the disc brake caliper needs to apply and release. If it doesn’t completely release, the brakes drag and experience premature wear. In extreme situations a dragging caliper can cause the automobile to pull while driving on the road. This condition can often be mistaken for the front end out of alignment. Common factory installed brake caliper slides need servicing during a standard brake job.

Let’s explain the words servicing the slides. The caliper slides accumulate brake dust and can experience corrosion due to their exposure to harsh conditions. These caliper slides are meant to be removed and cleaned when you’re performing a standard brake job. With that said, these same parts need to be lubricated with a specialized caliper lube before you reinstall them.

Caliper lube is manufactured to stand up to the extreme temperatures generated by automotive braking systems. In addition, this specialized grease remains waterproof even in harsh conditions. In most cases the applied lubricant will last as long as the friction pads. The factory installed caliper lube on the assembly line. Mechanics performing DIY brake jobs in the driveway should do the same. For retail automotive consumers, they should ask their mechanic if they cleaned and lubricated the caliper slides on their automobile during brake service.

Brake Pulsation and Noise

Many auto repair shops just quickly replace the friction pads and move on to the next car. In the industry, we call this a hang and go or a pad slap. During a hang and go operation all of the vital tips recommended by factory trained technicians get thrown into a trashcan. Although consumers might be happy with the price for a pad slap service, they will not be thrilled with how long they last. And the chances of possible problems they might experience in a short time of use increases exponentially.

When retail car repair shops apply the hang and go service to an automobile some of the first complaints from drivers becomes brake pulsation and noise when stopping. Let’s tackle the brake pulsation part first. In this situation professional mechanics recommend you replace the disc brake rotors. In the old days we would recommend a resurfacing operation for the original equipment rotors. However, in an effort to reduce the weight of the vehicle and save money, the rotors installed on modern automobiles don’t resurface well.

They use a composite material instead of pure steel. The other issue becomes the thickness of the rotor installed on the assembly line. These parts are already near their minimum thickness. This means that replacing the disc brake rotor remains the way to go. Thankfully, aftermarket companies offer these replacement parts at bargain prices for most automobiles. Unfortunately, on some German cars these parts carry a high price tag. However, even on German BMW automobiles you can find replacement parts under $200 each.

Problems with DIY brake jobs

The next problem we run into with a hang and go brake job becomes noise generated while braking. The noise itself is caused by a vibration of the friction pads. There are two things that help reduce the possibility of brake noise performed on a full service brake job. First, mechanics looking to achieve the best results should always replace the hardware. On disc brake systems these are stainless steel clips that firmly hold the brake pads in place.

On rear drum brakes, hardware includes the springs and shoe hold downs. Failure to replace these parts allows the brake parts to vibrate and cause brake noise. The second issue that can cause annoying disc brakes squeal also has to do with brake pad vibration.

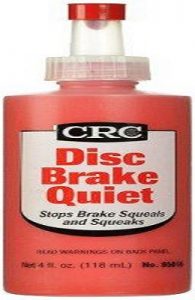

It stems from when the brake caliper piston applies the friction pads against the rotors. We need to dampen the vibration between the face of the piston and the back side of the inboard pad. High quality replacement parts include a vibration dampening shim on the inboard brake pad. When you buy cheap parts they often lack this shim. Some auto repair shops apply a silicone substance called disc brake quiet to the inboard pad. However, they would not have to do this if they bought high quality replacement parts in the first place. Disc brake quiet can wear down over time and annoying brake noise becomes the result.