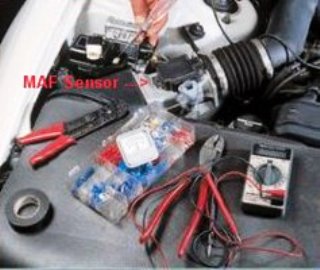

Mass airflow sensor problems can cause a variety of symptoms from the annoying to the must repair. We’ll discuss these in-depth on this page.

Also watch the video on how to clean MAF sensors without damaging the delicate part at the bottom.

Here are some problems a malfunctioning senor can cause. Rough idle, engine hesitation, lack of power and poor fuel economy.

However, the big one is a random stalling condition. I should also mention the older the part is the more likely problems are.

In the 80’s and through the 90’s these air density measuring devices were in a evolutionary stage.

Back in the early 90’s GM was making some pretty bad MAF’s. When I had a stalling complaint with no set codes I would do a light tap test at the connector area and see if the RPM changed.

If it does, it needs a new one. The mass airflow sensor can turn on the check engine light and set some strange codes. This depends on how bad the car is running. I have seen random misfire codes and o2 sensor faults set.

Often you can narrow down diagnosis using the set trouble code. However, when the MAF sensor malfunctions some faults will actually be symptoms of the root cause.

Take a P0102 for instance, which stands for low air volume or input signal to the computer. It can be a wiring issue, problems with the sensor itself or an actual air flow issue. We discuss this in detail below.

This is why you still need to start with the basics. Check for things that would be more common then a defective part.

A vacuum leak is an excellent example. This is where air gets pulled into the intake manifold without the computer knowing about it. In this scenario air bypasses the flow sensing element and you get a lean condition.Here’s another situation where the mass airflow sensor gets bypassed. It’s when the air duct that runs from the air filter housing assembly to the throttle body is torn.

This is a common condition on older, high mileage vehicles. It allows air to enter the engine without the computer knowing about it. Thus, symptoms and false trouble codes indicating a sensor failure are likely.

Contaminated Mass Airflow Sensor

If there is no vacuum leaks and the air induction hose is in good shape, it’s possible that a dirty mass airflow sensor is the problem.

This can display the same problems and symptoms as a defective part. Any vehicle with over 20,000 miles might experience problems due to contamination buildup on the heated element of the MAF sensor.

As a rule of thumb, the older the vehicle the more likely this problem is. Unfortunately, it can change the operation of the automobile for the worse.

As an example, in 1994 Ford came out with a technical service bulletin as well as Mazda, that outlined the test procedure for a contaminated mass airflow sensor.

Vehicle manufacturers eventually built in a self-cleaning mechanism into the part. It works by super heating the sensing element to burn off any contamination like a self cleaning oven.

On older vehicles that don’t have this function, a cleaning will be necessary at some point. I have an important tip for you that I learned the hard way. You should never use carburetor cleaner on a mass airflow sensor.

It can ruin a good part. There is an example posted in the video to follow. The chemicals are just too harsh and can damage the plastic. This can cause more problems than the dirty sensor did.

The CRC chemical company makes a specialized cleaner that removes any contaminants without damaging the plastic. There may be other manufacturers that make this cleaner, but make sure they are plastic safe.

How a Mass Airflow Sensor Works

The sensor pictured on the right, converts air flowing past a heat sensing element into an electrical signal. They use this as an input signal to the vehicle’s main computer.

The strength of the signal is determined by the energy needed to keep the element at a constant temperature above the incoming ambient air temperature.As the volume and the density of air across this heated element changes the temperature of the element changes. They adjust the current flow to the sensor to maintain this constant temperature setting.This method allows the computer to do an accurate analysis of the air entering the engine. Whether it’s hot, dry, moist or cold and even a high or low pressure affected by the altitude of the automobile is all determined by this calculation.

The condition of the air entering the engine is extremely important, because the denser the air the more oxygen it will contain. This changes the air fuel mixture and the injector on time.

Proper calculations control the emissions level and the fuel economy of the automobile. If the element that’s doing all the sensing becomes coated in crud, it will hamper the ability of the computer to analyze incoming airflow.

Not only can a contaminated mass airflow sensor cause hesitation and stalling, but it can also cause poor fuel economy and performance. Even if cleaning the sensor doesn’t solve all your check engine light problems it might not be a waste of time.

Opinions vary on how often you should clean the mass airflow sensor. Some mechanics will recommend to clean the sensor every time you replace the air filter. This is a good thing when you use the right cleaner.Bookmark this page and share with friends having car troubles.

How to clean mass air flow sensor video

For more information about things that can make your service lights go on, this next link will take you back to the section about check engine light problems.

For more information about the other kinds of car repair information that can be found on the you fix cars website this next link will take you back to the homepage where you can find out how to ask car repair questions.