This complete guide to engine valve problems will help you understand what can go wrong with this mechanical engine part. In addition, we’ll talk about why these parts fail and cost-effective ways to repair the damage. You’ll also find a section for those motorists that tried to drive through a deep puddle and suffered engine damage as a result. Finally we’ll talk about the term, “valve job” often associated with intake and exhaust engine valve problems.

How Engine Valves Work

The Wright brothers used an intake and exhaust valve set up in their aircraft engine built in 1903. All modern four stroke power plants still use an intake and exhaust valve today. Unfortunately, even though this technology has been around for more than 100 years it’s not always trouble-free.

In order to effectively diagnose specific engine valve problems, it’s a good idea to understand how they work. The intake valve allows an air and fuel mixture to enter an individual cylinder to power combustion. The exhaust valve opens to allow burned exhaust gases to exit the cylinder after the fuel burns. If the exhaust gases fail to exit the cylinder at the right time, then there’s no room for the next intake charge to enter. This causes an engine misfire condition.

Therefore, you can see that timing of the intake and exhaust valves becomes critical to the proper operation of an engine. Although the technology remains the same as in the Wright brother’s engine, automotive designers improved efficiency by adding larger diameter valves and in some cases multiple valves to increase volume, horsepower and fuel economy. You might’ve heard of the term VVT? This stands for variable valve timing and allows for precision adjustment of the opening and closing of the intake and exhaust valves on the fly.

Intake Engine Valve Problems

The piston pulls in air and fuel on the downward stroke of its travel. It’s necessary for the intake valve to open fully to allow the combustion chamber to fill with the volatile mixture. As the piston reaches bottom dead center the intake valve must close and seal. With this accomplished, the upward stroke of the piston creates compression required for complete combustion.

When an intake engine valve malfunctions it’s often this sealing ability that fails to work correctly. If compression leaks out from around the intake valve it gets pushed back into the intake manifold where it came from. This type of intake engine valve problem often causes a misfire condition.

More than likely the driver’s complaint includes a rough engine idle and lack of power. The telltale sign of an intake side issue is a popping sound heard through the intake system. More specifically, you can often open the air filter housing and hear compression leaking back through the intake.

Exhaust Side Engine Valve Problems

As mentioned above the exhaust valve has an important task to accomplish. It must allow the waste product of combustion to efficiently vent into the exhaust system. As mentioned with the intake manifold, the exhaust valve must also have a perfect seal to allow proper compression of the air fuel mixture.

If the sealing surface of the valve fails, compression leaks out of the exhaust system. Not only does this reduce the efficiency of the combustion process, but it can allow raw fuel to enter the catalytic converter. This is the number one enemy of this expensive emission component. As with the intake valve malfunction, when the exhaust valve develops problems, you can often hear a rhythmic popping through the exhaust system.

Terminology Associated with Valve Problems

You might hear a mechanic say you have a burned valve. We associate this term with an overheating of the valve face. This causes imperfections in the sealing surface. When the valve doesn’t seal properly, you’ll hear that rhythmic popping sound through the exhaust system. This problem only gets worse with time. The more heat leaking past the valve face, the more damage occurs.

Another term you often hear a lot when you’re visiting those car forums is people talking about getting a valve adjustment. This isn’t something that normally applies to most modern day engines. With that said, there are exceptions to the rule. In the muscle car days valve adjustments were done to solid lifter automobiles. When the hydraulic lifter came on the scene, it reduced the need for constant valve adjustments.

The sure fire way to verify whether your engine needs a valve adjustment is to look at your vehicle specific auto repair manual. If the manufacturer requires this adjustment they provide the procedure and the specifications to perform the valve adjustment properly. If you dig into the engine valve section you will probably find that it says no valve adjustment required. This is because the hydraulic lifters automatically compensate.

Engine Valve Problems Caused by Water

If you fail to heed the wise words of, “turnaround don’t drown” when you see a deep puddle, you can cause your own engine valve problems. Engines cannot compress a liquid and this remains the reason water becomes so destructive to an internal combustion engine.

This is why manufacturers atomize the fuel before it’s sucked into the combustion chamber. The only thing that belongs in this area is air and gas vapor. When water enters the cylinder something is going to break.

Sometimes it’s the piston. And sometimes it’s the engine valve. With that said, there are other degrees of damage related to how much water enters each cylinder. As an example, the valve might bend a little from trying to compress the water. This stops it from sealing properly and can cause all the problems mentioned above. The next question is how to repair engine valve problems.

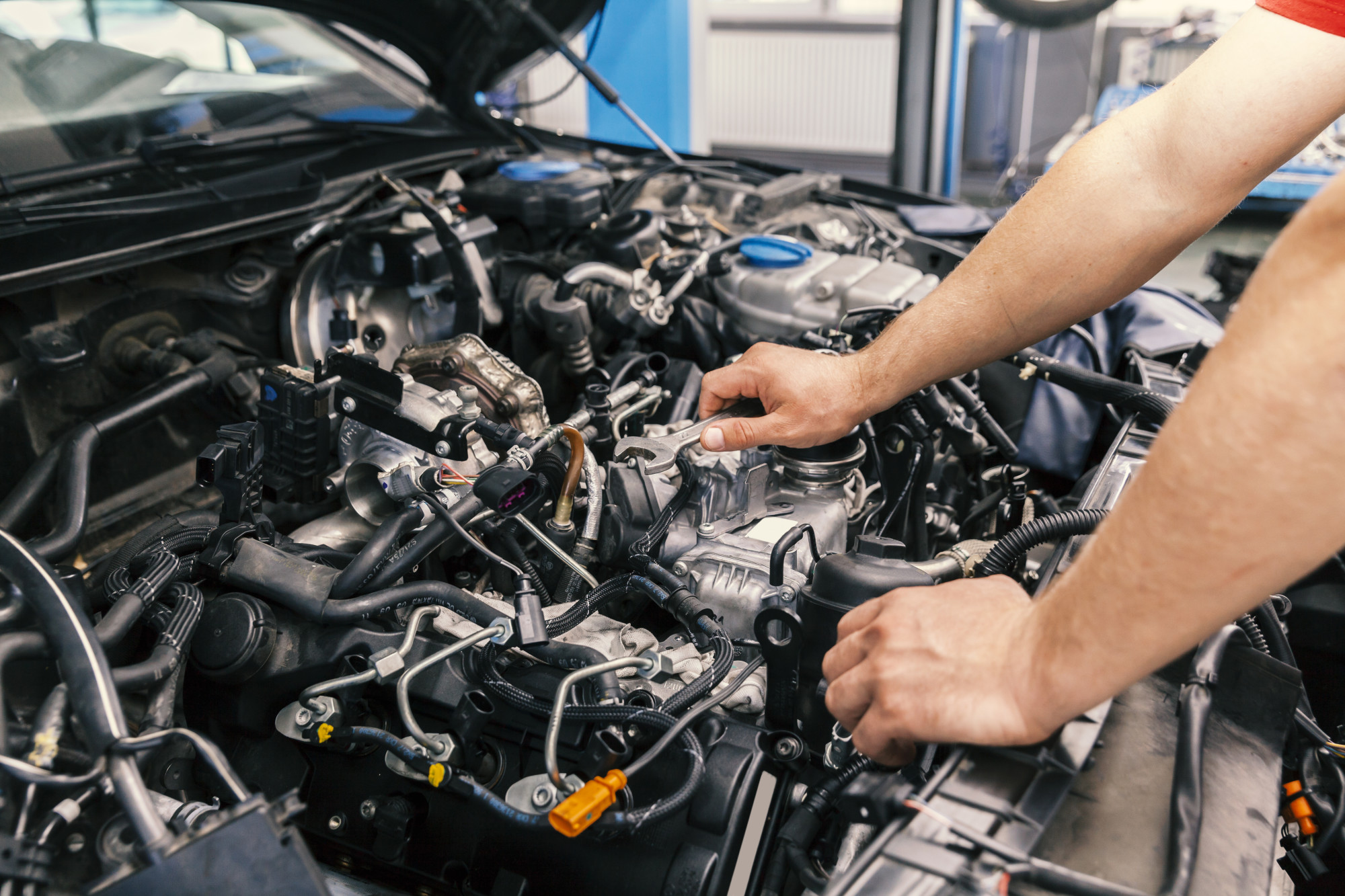

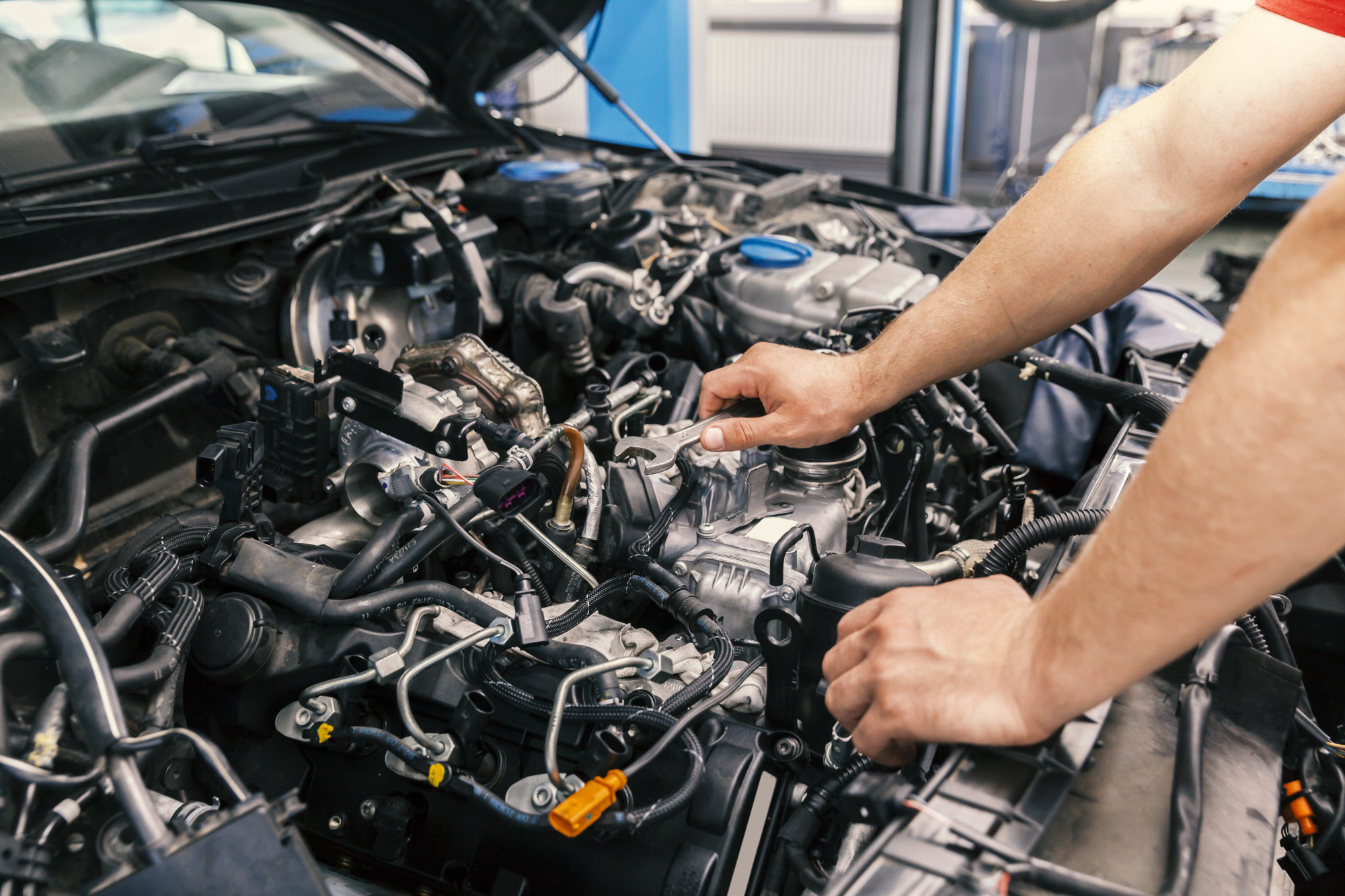

Properly Repairing Engine Valve Problems

In the old days we use to remove the cylinder head and pull out the individual valves to repair them. As time went on we started sending out the damaged cylinder heads to machine shops. Why not let them fix it using their precision equipment? All of these methods led to a necessity to streamline the process. Now it is more common for auto repair shops to purchase rebuilt cylinder heads for their customers. Auto-parts companies that specialize in rebuilding cylinder heads work with such volume that they’re able to provide the cheapest and most effective way to solve engine valve problems by replacing the whole head.