What is Wrong With my Car AC

Since I turn wrenches in the oppressively hot and humid state of Florida I am familiar with car air conditioning problems.

Fellow Floridians come to me and ask what’s wrong with their car AC system year-round. However, in the summer months this question becomes a plea for help.

Automotive air conditioning problems can range from an inexpensive minor refrigerant leak all the way up to a wallet crushing AC compressor failure. On this page we’ll review the pressure readings you’d expect to find on your air conditioning manifold gauge set for the most common automotive air conditioning issues.

Some of you might be thinking, but I don’t own a set of manifold gauges. If you have some do-it-yourself skills this is a tool to add to your collection. With the cost around $65 they can pay for themselves on the first use.

Pictured above is the set I bought 20 years ago. Although most of my tools are high end or brand name, these gauges are from an off brand supplier. The fact they held up and provided so much value over the years is proof you don’t have to overspend on these tools.

Even if you’re unable to complete the repairs the manifold gauges point to, the knowledge can still save you money. How you ask? Well unfortunately, rip off AC repairs are common in some areas of the United States.

Learning how car AC works and narrowing down the possible causes of your exact problem, turns you into an educated auto repair consumer. Now, let’s find out what these common air conditioning problems look like when converted into pressure readings.

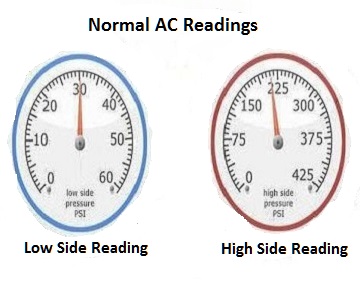

Normal Air Conditioning Pressures

We can’t identify problems with the air conditioning system by using a set of manifold gauges unless we know what they’re supposed to read when everything is good. I pulled the graphic on the right out of a really old air conditioning manual. It shows that the ideal low pressure reading is around 30 psi. This was true when they used R12 Freon.

With R134-A refrigerant the ideal low side pressure reading is just a little bit higher. I would like to see a low side pressure between 33 and 36 psi to provide the best cooling on a hot summer day. On the high pressure side the gauge reading is approaching 225 psi.

This is a good number to shoot for depending on the temperature and humidity on that day.

The hotter and more humid it is, the harder the AC compressor will work on your car. As a result the high side pressure readings can climb into the 250 psi range and still be considered normal.

In this situation the low side will probably creep up as well. And this is why the output temperature at the AC vent doesn’t seem as cool on these extremely hot days.

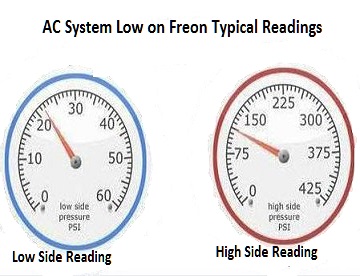

AC System Low on Freon Pressure Readings

When you’re car air conditioning system is blowing warm air out of the vents the number of possible causes turns into an amazingly long list.

However, by connecting a set of AC manifold gauges you can quickly shorten this list of possibilities. In the image on the right you’ll see the low side reading is far below the 33 to 36 psi pressure you would like to see.

The high side is also far below what you would normally expect to see during summer operation. In fact, both of these pressure measurements are so low they might activate the cut out switch. This is how car makers turn off the compressor to protect it from damage.

We lubricate the AC compressor with an oil mist contained in the Freon mixture. If the refrigerant is low, oil circulation decreases to the point where it may fail to lubricate the compressor properly.

When manufacturers disengage the compressor under these circumstances they’re probably trying to save themselves money in warranty repairs.

Fortunately, it carries over to when the vehicle is out of warranty. This can save you from having to replace the compressor, which is one of the worst-case scenarios. You should never bypass the low cut off switch to test the AC system.

When you have low readings on both the low and high side you can add an individual can of refrigerant to see if it boosts the pressure reading. If it does then you probably have a Freon leak somewhere.

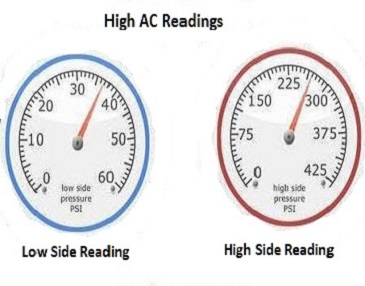

Elevated High Side Pressure Readings

As we work our way down diagnosis of the root cause of the problem becomes more difficult. In the graphic to the right, you can see that the low side is slightly elevated, but still good enough to provide cool air. However, the high side pressure reading is starting to creep towards the 300 psi range. The good news to take away from this type of reading is the compressor is certainly working.

The bad news is the compressor is working too hard. And the discharged air is probably starting to warm up at the vent. When I see these readings, the first thing I go for is the AC condenser mounted in front of the radiator.

Improper airflow through the air conditioning condenser can cause elevated high side readings.

The problem can range from a restricted condenser blocked by road debris like paper plates or maybe the condenser fan isn’t working properly. Whenever the AC compressor turns on the condenser fan should run. Although airflow issues are the most common reason to see excessive high side pressures, it’s not the only possibility. Blockages inside the air conditioning system or a malfunctioning expansion valve can also cause these results.

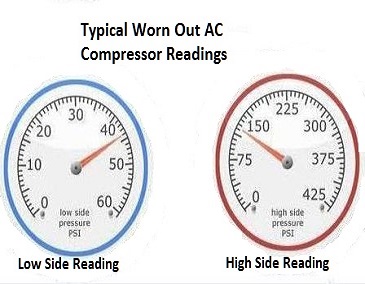

Pressure Readings with a Worn Compressor

It’s challenging to find a harder working component than the automotive air conditioning compressor.

However, even on the high end cars, these components can get tired after several hundred thousand miles of operation.Pictured to the right is a typical manifold gauge reading on a fully charged system with a worn-out AC compressor. As you can see the low side is above specification. In addition the high side is way below where it should be.

You can see that this compressor is engaged and functioning. Unfortunately, it’s unable to reach the pressures required to manufacture cold air. As in the above example with elevated high side readings further diagnosis should be performed before we condemn the compressor.

The next step I would take is to recover the system and find out exactly how much Freon is installed. I would also want to verify proper expansion valve operation.

If the automobile has an orifice tube instead of an expansion valve I would remove it for inspection. On cars with an orifice tube the little plastic part will have a mesh screen to catch debris.

If I find metal fragments in this area, it’s most likely material from the internal workings of the compressor. If you believe you have a air conditioning compressor malfunction it’s important to verify if metal chips have spread through the system. These tiny fragments can cause repeat AC problems and failure of the replacement unit.

So What’s Wrong with Your Car AC?

The system can communicate with you in its own proprietary language. It makes an attempt to chat with mechanics by speaking in pressure readings. If that fails the system will scream for help with more urgent AC noises.

Although this language can point you in the right direction it will ultimately take some hands-on diagnosis to verify failures. Since I work with these complex systems quite often, this website has many in-depth articles on the subject.

I’m a firm believer in gaining a complete education on the automotive system you are having a problem with. You can head back to the main automotive air conditioning page for more information. However, a lot of people just want to know how to recharge car AC systems without learning the details of how it works. That’s fine, but knowing how it’s supposed to work when everything is functioning as per the design intent will help you identify problems when things go wrong.