Car Suspension and Steering Systems

This is the opening page for the car suspension and steering systems section of the you fix cars website. This page will be a brief overview of the core of the vehicle, which is the frame. All steering and suspension parts attach to the frame. Below will be articles that cover these individual attaching parts.

If the frame isn’t straight or its been tweaked in an accident many problems and even safety concerns can develop. The car suspension system has greatly changed through the years. Customer input and new technology brought about these changes, so we can have sports car like handling while maintaining a luxurious ride.

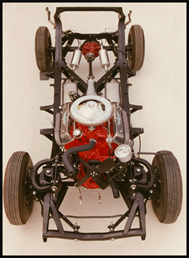

To provide a rigid structural foundation for the vehicle body and a strong place to anchor the suspension system a frame of some type is necessary.

There are two basic frames in use in today’s automobiles, the box and uni-body. There are several variations of the two main types. The conventional box frame construction is also called the body over frame type.

In this instance the frame is the automobiles foundation. The body and all major parts of the vehicle or attached to this frame. It must provide the support and strength needed at the attachment points. The box frame is unique in that it is completely independent from the rest of the automobile. The first thing to roll down the assembly line is the bare frame.

In most instances of full frame construction rubber body mounts are installed between the hard metal frame and the sheet metal of the body. These can and will usually out last the automobile itself (rust never sleeps).

A uni-body frame actually looks like part of the sheet metal of the car but with some characteristic differences. In some cases the manufacturing process will layer sheets of metal together and bond them to provide the backbone to attach car suspension components. The unibody design significantly lowers the total weight of the automobile and that in turn can increase fuel mileage.

Types of Automobile Springs

When people think of car springs they often think of a coil or leaf spring. My first car was a 1974 Dodge Charger that had a torsion bar front suspension. This is where the bounce is facilitated by twisting a solid steel bar.

Today I drive a 2004 Chevrolet Blazer. My blazer also has torsion bar front springs. The span between these two vehicles is 30 years. I would think that if this type of front spring is still being used then It must be reliable. With a torsion bar suspension it is important to check ride height before aligning the vehicle.

The automotive spring is the component that absorbs shock forces while maintaining correct riding height and steering angles. If the spring is worn or damaged the other suspension elements can shift out of their proper alignment.

Various kinds of car suspension springs are used in today’s automobiles. These include the coil spring, the torsion bar, the leaf spring and even air springs. Every automotive spring I’ve seen uses some type of rubberized mount to attach the spring to the frame.

As with the heavy duty body mounts pictured above, these heavy rubber mounts are designed to last a lifetime of the vehicle without replacement. But in some extreme use cases or vehicles that are older than 20 years replacement may be required at some point. All of the vehicle’s weight above these frame mounted springs is considered as sprung weight. The weight of those components not supported by the springs is known as unsprung weight.

Examples of unsprung weight would be the vehicles steering parts such as tie rod ends and drag links, as well as the differential on rear wheel drive cars.

Diy repairs on car suspension or steering systems should only be performed by people with prior experience. If you have replaced ball joints and tie rod ends in the old days like me, then you will find modern procedures familiar and on some models the repairs are even easier. Only a few late model cars require a ball joint press anymore.

Driveway mechanics should always have their worked checked by a professional auto mechanic when in doubt. Forgetting a cotter pin or performing repairs over your head could get someone hurt.

Automotive Steering and Suspension Help

A good front end alignment is hard to get. As a mechanic let me explain why this is. Discover my insider secrets to increasing your chances of getting a quality wheel alignment. Have you ever bumped a curb and wondered what to do next? Shops with an alignment rack might want you to think you automatically need an alignment service after a car hit a curb.

A friend with a Nissan Maxima received an estimate to fix her suspension thump noise for over 3 grand. After a second opinion and a consultation she got the car fixed for under $200.

The struts or shocks is what keeps the tire on the road. Learn how to diagnose bad ones. Take a look at some information about replacing automotive shock absorbers.

Lets get into automobile steering parts. Things like idler arms and center links are popular up sells. But do they really need to be replaced? Can you do it yourself? See the page about automotive steering parts. Here is a true story about what happens when you trust someone to grease your front end. Learn about do it yourself chassis lubrication. Another item that gets sold during alignments are tie rod ends. These are often recommended by mechanics. The question to ask is whats the free play specification and the actual measurement. Learn about these car steering parts before getting an alignment. Did you ever wonder why car-makers use the design of the their suspension as a sales tool. Or have you ever wondered how to check for defective parts on your own independent front suspension.

Modern steering racks are most often found on unibody cars. But are expanding to full frame trucks as well. See a brief overview of the problems and repairs associated with rack and pinion steering. Are adaptive suspension systems ready for prime time? Does the words on the fly scare you? My opinion on the latest active suspension systems.